Introduction

Artificial Intelligence (AI) is rapidly weaving into the fabric of everyday life including the ancient craft of stonework. From how we view stone, to our photography of each slab and piece, to how we arrange the art of the layout, to how we carry and place each sacred piece. AI’s influence is already profound.

In the large scheme of things, at this pivotal moment, society must ensure that this integration happens in a healthy, ethical manner. An AI-integrated world can either greatly uplift human life or, if misused and left unchecked, invade privacy and exacerbate inequalities and risks. By proactively building ethical principles into AI development now, we can harness transformative benefits while avoiding serious pitfalls. Blue Pearl maintains a staff of highly experienced and trained artisans who are involved in the creating beauty in look, feel and transition with the help of computers.

AI Transforming Daily Life

In transportation, for example, AI powers self-driving cars and smart traffic systems . These technologies could drastically reduce accidents (since the vast majority of crashes stem from human error) and cut down traffic jams, making commutes safer and greener. In healthcare, AI-driven diagnostic tools can analyze medical scans or patient data faster and often more accurately than humans – detecting diseases at early stages that doctors might miss, and suggesting personalized treatments. Meanwhile in education, AI tutoring systems personalize lessons to each student’s needs, helping children learn at their own pace and giving extra support where needed. These relatable examples show how, with conscious and ethical design, AI can improve safety, well-being, and opportunity for people in everyday life.

AI in Construction and Design

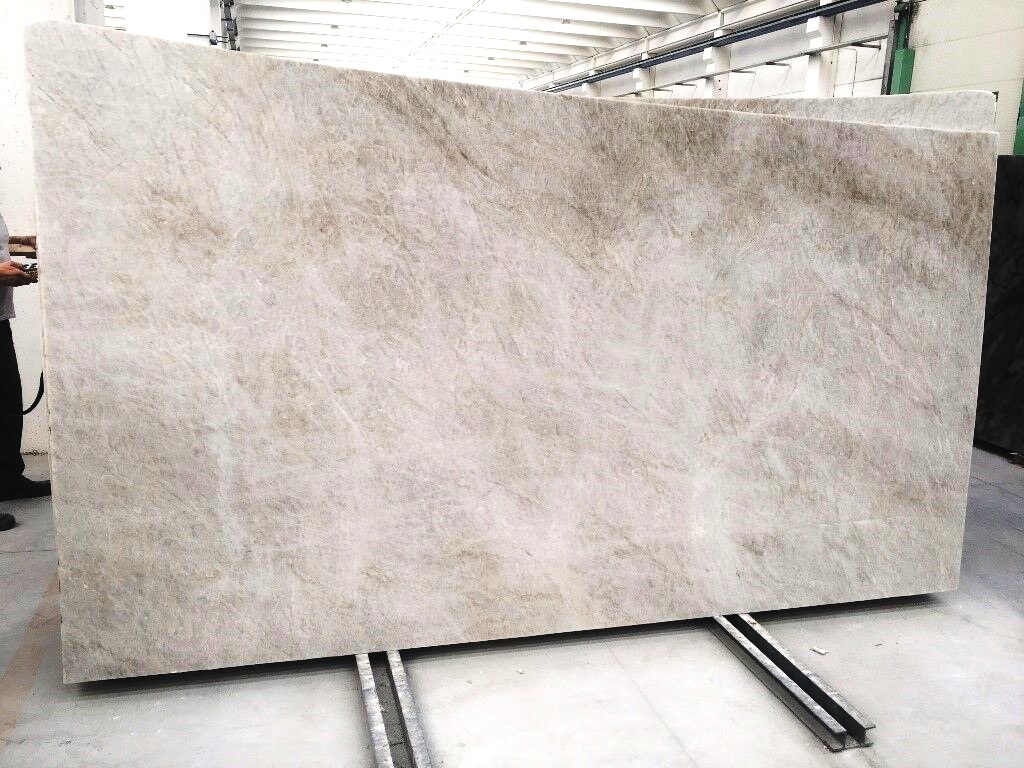

Beyond personal life, industry-specific cases demonstrate why ethical AI is crucial. In the construction and design sector, for instance, AI-driven software can help architects and builders plan projects and choose finishes like marble or tile with optimal efficiency and creativity. An AI system might suggest tile design patterns or interior layouts, or calculate how to cut marble slabs with minimal waste – combining aesthetic vision with practical savings. Supply chains for building materials are likewise being improved: AI can forecast demand for materials, track shipments in real-time, and flag quality or ethical issues in sourcing, ensuring the right products arrive on time and meet standards. By integrating AI thoughtfully in these specialized areas, companies reduce waste and delays while upholding high quality and fairness in their operations.

Leading an increasingly authoritarian world toward ethical AI requires strategy, courage, and systems-level thinking. You cannot appeal to authoritarian leaders with moral arguments alone—but you can leverage power, pressure, and proof in ways that reshape incentives. Here are a few guiding principles to keep us safe:

Ethics is Power

Authoritarian regimes don’t prioritize ethics—but they do prioritize control, economic advantage, and legitimacy. So:

Show how transparent, fair AI earns international trust and opens doors to trade, investment, and influence.

Demonstrate how ethical AI reduces resistance and rebellion by keeping populations safer, more employed, and less volatile.

Expose how corrupt, biased AI systems weaken legitimacy and trigger unrest or global backlash.

Build International Norms That Are Hard to Ignore

Create strong alliances among fair minded companies, democracies, NGOs, and industry coalitions to form a global ethical AI frameworkstarting at home:

Work with honest ethical companies

Binding agreements (like the EU AI Act)

Certification systems for ethical AI (like CE for electronics or LEED for green buildings)

Shared data, audits, and red-flag mechanisms

Decentralize the Infrastructure

Support open-source AI models for All

Push for edge computing (where devices process data locally)

Advocate for data sovereignty: individuals and local communities owning their data

Empower Ethical Builders

Even in authoritarian systems, scientists, engineers, and civil servants often want to do the right thing. Quietly support them.

Fund ethics education in tech schools worldwide

Create safe reporting systems and whistleblower protections

Build bridges between international researchers and those under repressive regimes

Protect individuals from being watched and controlled by AI

Change often begins with a small cadre of ethical insiders who are equipped, connected, and visionary.

Reveal the Hidden Costs

Reveal the real human cost of unethical AI:

False arrests from flawed facial recognition

Lives destroyed by AI false credit or job denials

Psychological damage from AI-driven propaganda or manipulation

Create A New Civil Society for the AI Age

Encourage local and national government to refuse exports of harmful surveillance tech

Support grassroots digital rights orgs (e.g., Access Now, EFF, Article 19)

Pressure multinational companies to uphold ethical AI globally, not just in Western markets

An Ethical AI powered Society is a Civill and more successful and happier Society.

Commitment to the Human Spirit

At Blue Pearl, we’re committed to the human spirit.

We believe you are an original — and your spaces should feel that way too.

Originality isn’t mass-produced. It’s made with care, curiosity, and just a little rebellion.

We celebrate the diversity of our guests — those who share their unique vision, stories,

and unapologetic love of style, color, texture, and soul!

We believe humanity must remain an integral part of the living world — shaping, sensing, creating in harmony with nature.

As technology evolves, we do not retreat. We will join forces with AI not to replace ourselves, but to refine ourselves — to sharpen intuition, deepen creativity, and honor sensibility.

We stand for craft guided by soul, innovation rooted in beauty, and progress that remembers where it came from: Earth, hand, and human intelligence.